Introduction to 3D Scanning Technologies

3D scanning is a groundbreaking technology that captures the shape and dimensions of real-world objects to create precise digital models.

This process involves using lasers, light, or x-rays to measure the physical properties of an object and convert them into a digital format. The resulting 3D models can be used for various applications, including inspection, reverse engineering, and design.

Industries such as aerospace, automotive, healthcare, and education have embraced 3D scanning for its ability to provide accurate and detailed representations of physical objects. In aerospace, for example, 3D scanning is used to inspect and maintain aircraft components, ensuring they meet strict safety standards. In the automotive industry, it aids in the design and manufacturing of vehicles by providing precise measurements of parts and assemblies. Healthcare professionals use 3D scanning to create custom prosthetics and implants, while educators utilize it to teach students about engineering, marketing, and 3D animation projects.

Benefits of Combining 3D Scanning and 3D Printing

The combination of 3D scanning and 3D printing has revolutionized product development by enabling rapid prototyping. This process involves scanning an object, modifying the digital model, and then printing the new design. This cycle can be repeated multiple times, allowing designers to iterate quickly and efficiently.

One of the primary benefits of this combination is the reduction in time-to-market and development costs. Traditional prototyping methods can be time-consuming and expensive, but with 3D scanning and printing, prototypes can be created in a matter of hours or days. This speed allows companies to bring products to market faster and at a lower cost.

Additionally, 3D scanning and printing facilitate the reproduction of legacy parts. Many industries rely on older equipment that may no longer be in production. By scanning these parts, companies can create digital models that can be modified and printed, ensuring the continued operation of their machinery.

Customization is another significant advantage. 3D scanning allows for the creation of personalized products tailored to the specific needs of end-users. This capability is particularly valuable in healthcare, where custom prosthetics and implants can greatly improve patient outcomes.

HP DesignScan Competitive Advantages

HP DesignScan stands out in the market due to its competitive advantages. Manufactured, under license from HP, by Creaform a global leader in portable 3D measurement solutions, the HP DesignScan offers high-quality and reliable performance.

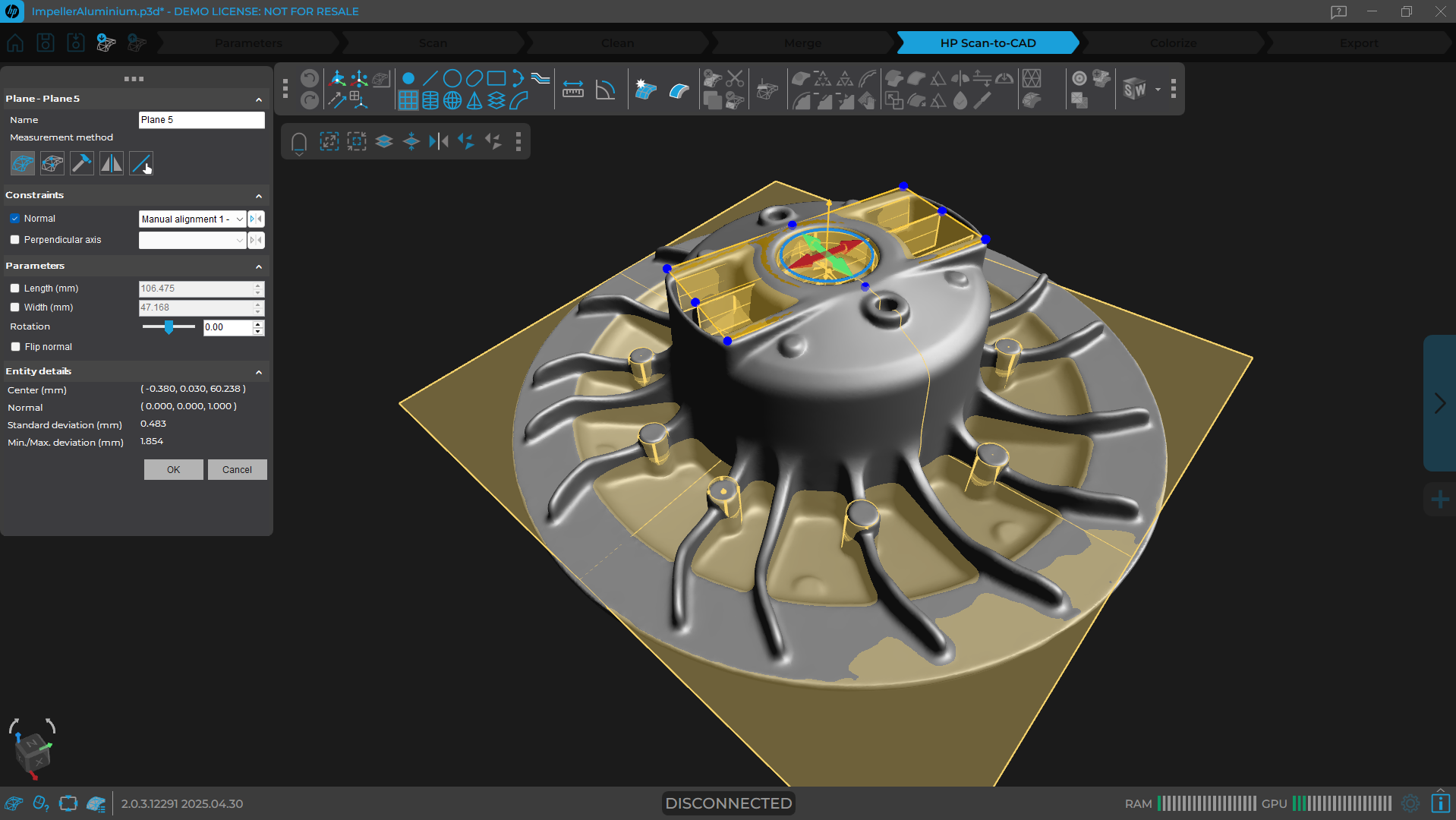

One of the key features of HP DesignScan is its intuitive software interface. The software provides real-time mesh generation, allowing users to see the digital model as it is being created. This feature ensures that any errors or omissions can be corrected immediately, saving time and improving accuracy. Additionally, the software seamlessly integrates with CAD programs, making it easy to incorporate scanned data into existing design workflows.

HP DesignScan also boasts high-resolution scanning with color capture. This capability allows for the creation of detailed and accurate digital models that include color information, which can be beneficial in marketing, gaming, and film projects.

The device is lightweight, portable, and easy to use in a wide range of environments. Whether in a factory or an office, the HP DesignScan can be deployed quickly and efficiently. Its portability ensures that users can capture data wherever it is needed, without being constrained by the location of the scanning equipment.

Enhancing Workflow with HP Multi Jet Fusion 3D Printing

HP Multi Jet Fusion (MJF) 3D printing technology complements the capabilities of HP DesignScan by providing a powerful and efficient method for producing high-quality parts. MJF technology uses a unique process that involves applying a fusing agent to a bed of powder material, which is then exposed to heat to create solid layers. This process allows for the production of parts with fine details, smooth surfaces, and excellent mechanical properties. The scans captured are ready to migrate to 3D printing workflows, including HP’s Metal Jet Technology.

Combined with HP DesignScan, MJF technology enhances the overall workflow by enabling a seamless transition from scanning to printing. The high-resolution scans produced by HP DesignScan can be directly used to create accurate and detailed 3D prints with MJF technology. This integration ensures that the final printed parts closely match the original scanned objects, reducing the need for additional modifications and iterations.

The combination of HP DesignScan and HP MJF technology also allows for greater design flexibility. Designers can easily make changes to the digital models based on the scanned data and quickly produce new prototypes using MJF printing. This iterative process enables faster development cycles and more efficient product testing.

HP Metal Jet technology also extends the capabilities of HP DesignScan by enabling the production of high-quality metal parts directly from scanned data. Using a binder jetting process, it deposits a liquid binding agent onto layers of metal powder, creating a part that is later cured and sintered to achieve high density and strength.

This method allows for intricate geometries, lightweight designs, and mass customization without the constraints of traditional manufacturing. When paired with HP DesignScan, the workflow ensures high-resolution scans translate into precise metal components, accelerating time-to-market and supporting small-batch production for in demanding industries such as automotive, medical, and consumer goods.

For additional information, you can check out this recorded webinar, which showcases how 3D scanning technologies, especially when paired with 3D printing, are making a significant impact. Discover the impressive capabilities provided by combining the HP DesignScan with HP’s 3D printing solutions, an effective approach for industries aiming to enhance innovation and streamline their product development workflows.

- Article

- Related